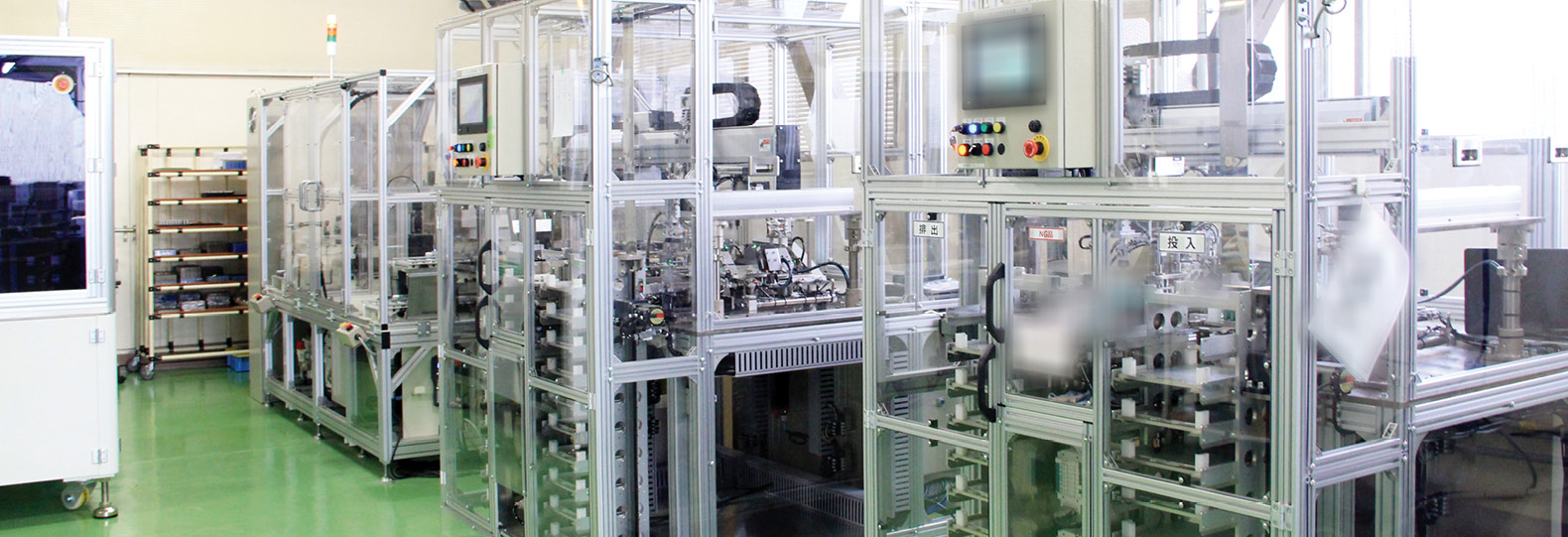

Automated production systems

At Suzuki High-Tech, to respond to global changes and optimize QCD,

we have actively introduced DX into our automated production systems.

As a result, we have been able to improved quality and productivity.

To improve performance and reduce costs, we have introduced mass production equipment that operates 24 hours a day.

We have a full range of analysis, measurement, and inspection equipment and are actively work on automation.

Because we are able to completely conduct the plating evaluation in-house, we are able to meet the customer’s specifications and provide customer’s satisfaction.

Automated plating process

We have fully installed production equipment that can provide products with high quality that meets the strict quality requirements and stability of automotive and semiconductor parts.

We also have automated lines of hard chrome plating and electroless nickel plating,

and we can provide processes that satisfy customer requirements from prototyping to mass production.

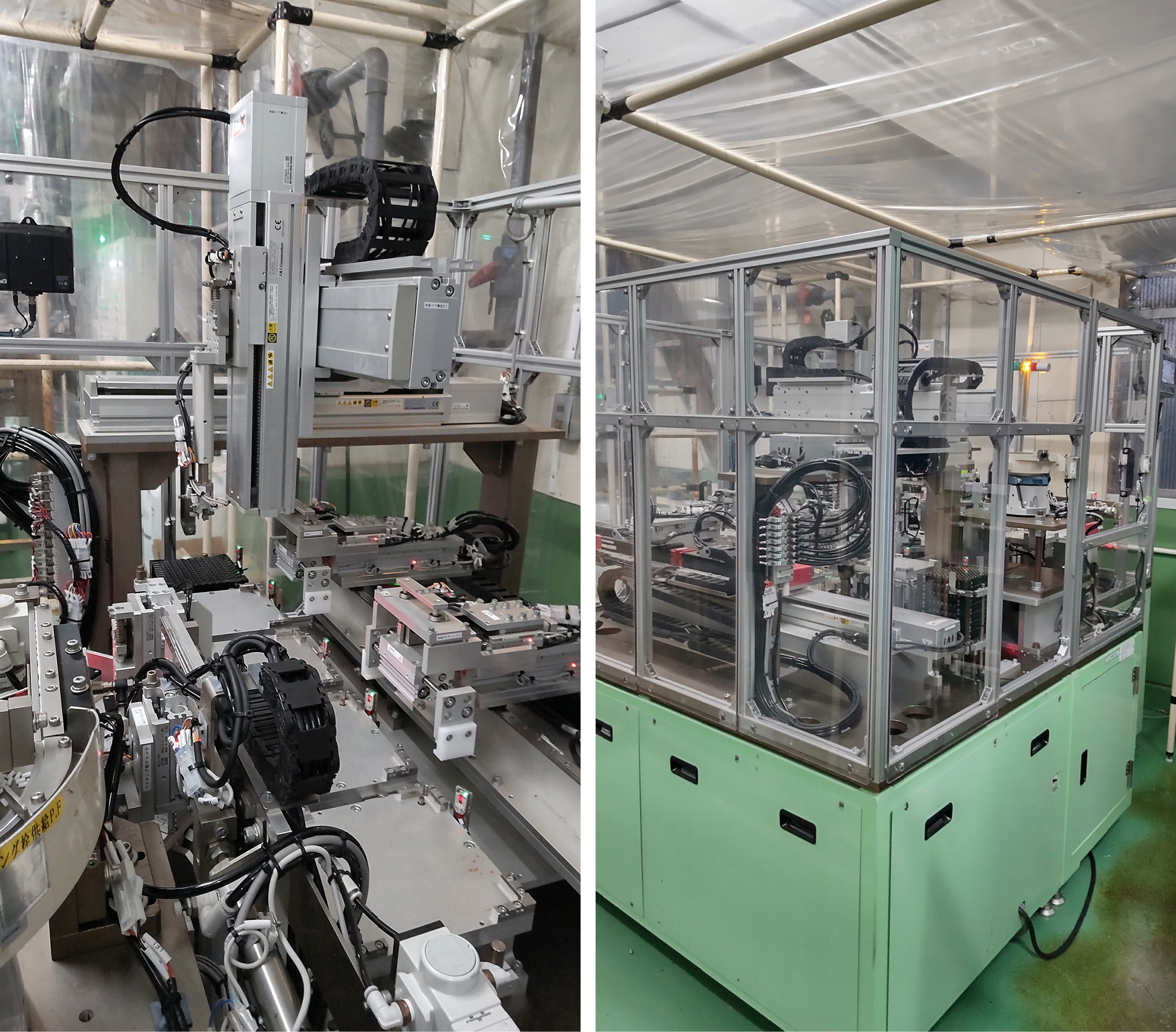

Automated masking machine

Automated inner bit removing machine

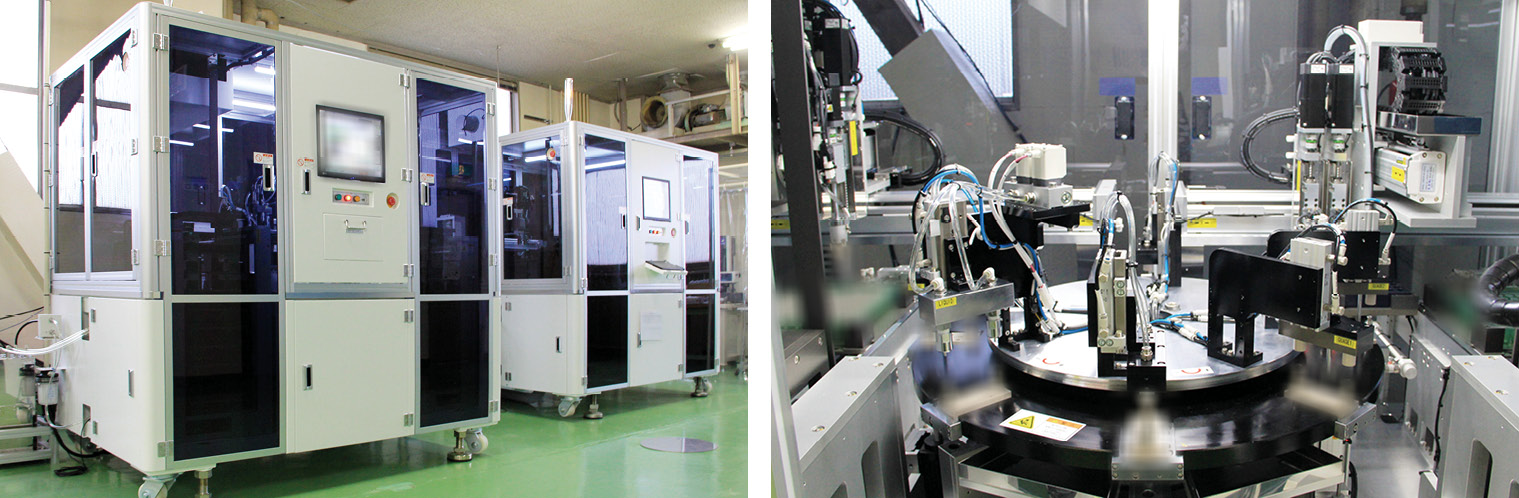

Automated film thickness inspection machine

Automated visual inspection machine

Automated x-ray fluorescent film thickness inspection machine