FACILITY

Suzuki High-Tech has various equipment such as production systems, automation systems, quantitative analysis instruments and surface analysis instruments, and also promotes the reduction of defects and the improvement of production efficiency.

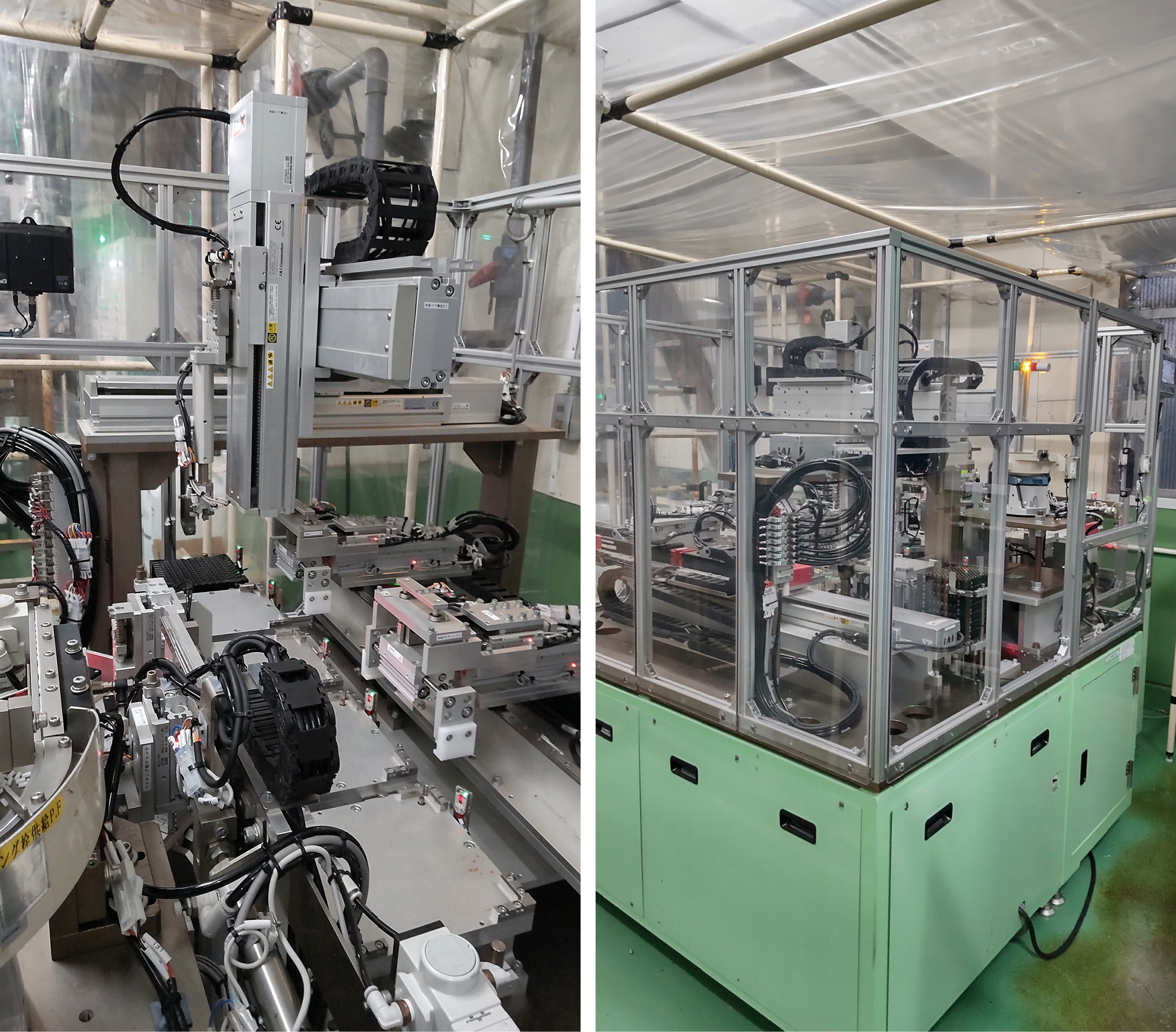

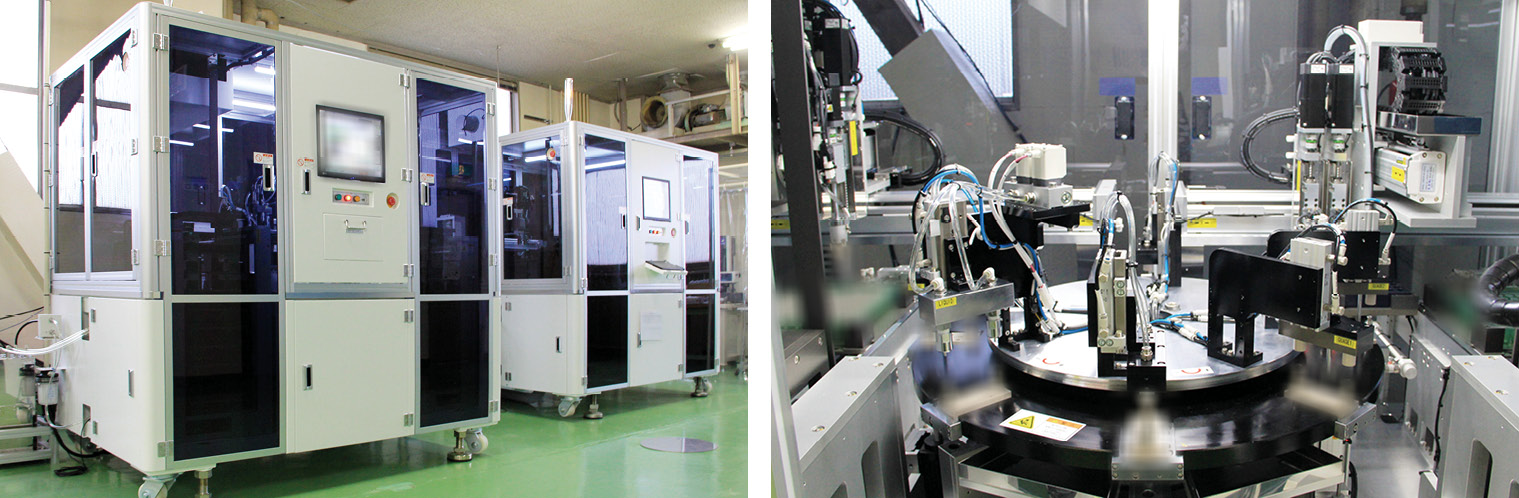

Production line with automation

Plating process automation line

Automatic masking device

Automatic internal diameter bit remover

Automatic film thickness inspection device

Automatic appearance image inspection device

Automatic fluorescent X-ray device

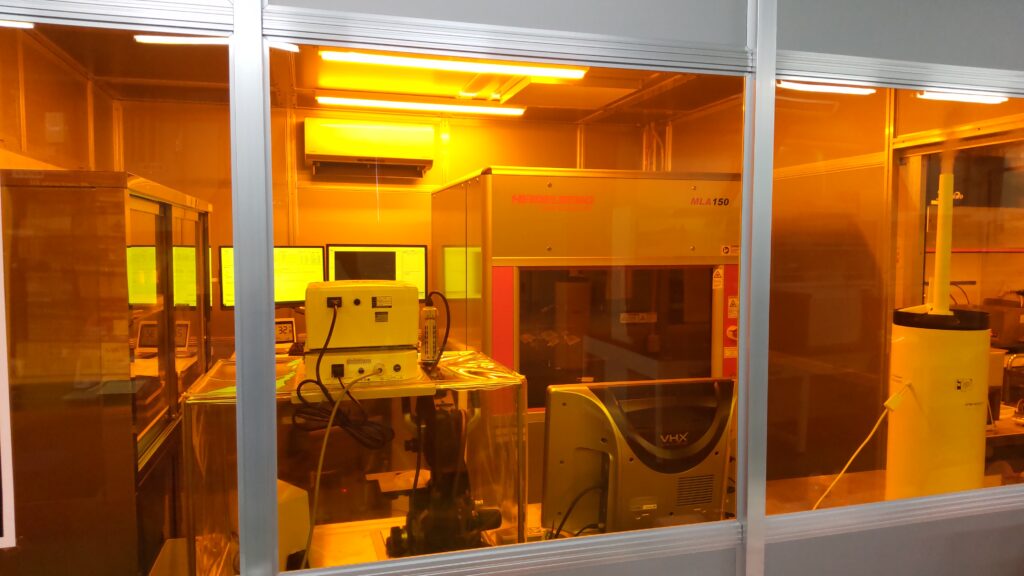

R&D equipment (photolithography, precision electroforming, measuring equipment)

Maskless laser direct drawing device

Heidelberg Instruments MLA150

A non-contact laser direct writing system that does not require mask. Equipped with two types of laser wavelength light sources, h-line (405 nm) and i-line (365 nm), with twice light intensity. High-speed binary exposure and 3D grayscale exposure enable resist formation that meets a wide range of application from thin to thick films. Alignment accuracy is within ±1.0 μm, fine hole opening accuracy is ±0.5 μm, minimum drawing size is 1 μm, and maximum drawing range is φ8 inch to 200 mm square.

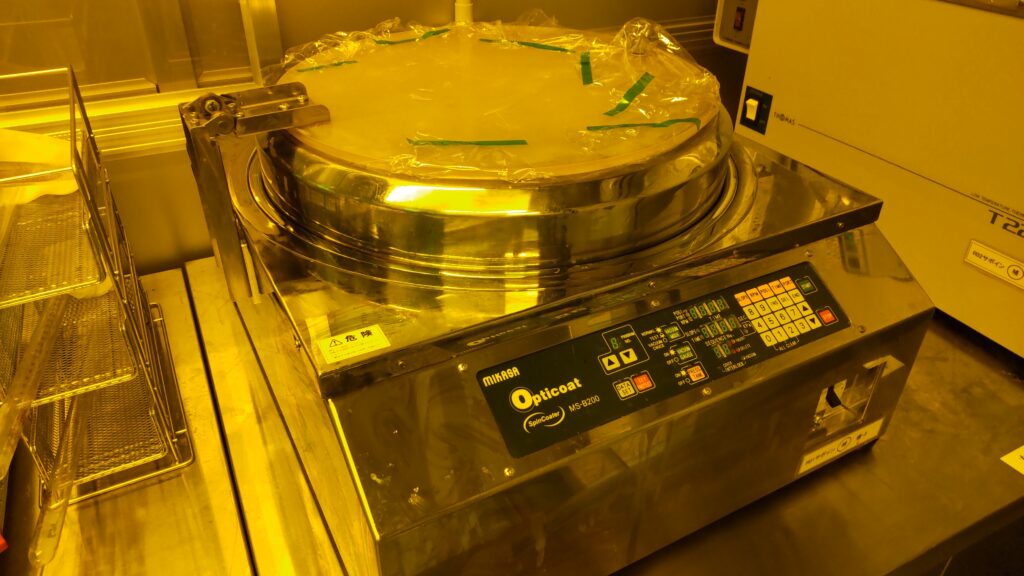

Spin coater MIKASA MS-B200

Equipment that rotates and coats liquid resist in the coating process of photolithography. 2 to 8 inch compatible.

Compact developer with temperature control function

Actes Kyosan ADE-3000S.

A tabletop type spin-developer that good at developing high aspect ratio pattern with excellent resolution. It is able to process both thin or thick films, and automatic continuous processing is possible without operator error.

Plasma cleaner

SUMCO PC-300

Batch-type oxygen plasma dry cleaning equipment used for photoresist ashing, mold cleaning, surface modification of organic films, and removal of organic contamination layers. There are two available processing mode, RIE mode and plasma mode, so it is possible to perform optimal processing according to the type of substrate.

Clean room class 1000

Class 1000 R&D clean room for all photolithography processes such as substrate cleaning, coating, PAB, exposure, PEB, development and hard baking. Yellow light is used to cut the ultraviolet rays.

8-inch compatible multi-jet electrode active-system electroforming plating equipment (3 units)

Plating is performed while rotating an 8-inch wafer substrate under optimized jet and flow velocity conditions, achieving a film thickness distribution within ±5% within the 8-inch surface. Different types of electroforming plating solutions such as palladium-nickel plating, nickel-cobalt plating, nickel sulfamate plating, etc. are available. (Photos omitted due to know-how included)

12-inch face-up electroforming plating equipment (1 unit)

A face-up type fully-automatic plating equipment that is advantageous for thick-film electroforming plating. Equipped with an automatic analysis and replenishment system for plating solution additives, an automatic pH adjustment function, and day and night automatic operation function, make it possible to handle any electroplating products from thin to thick films. (Photos omitted due to know-how included)

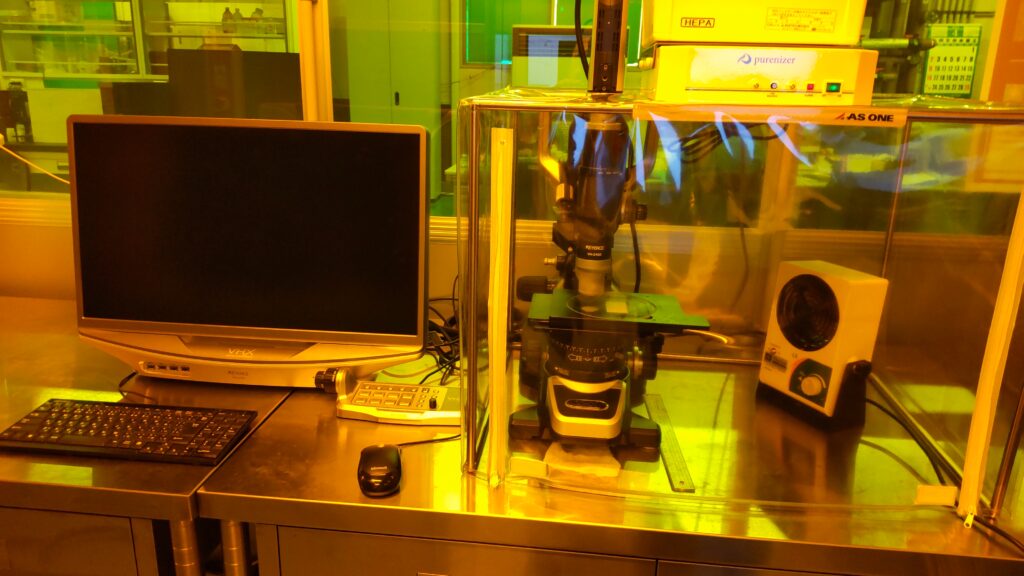

Digital microscope

Keyence VHX-970F

Used for process inspection of resist formation and electroforming, and also shipment inspection of micromesh and filter. It is possible to measure down to the order of 0.1 μm.

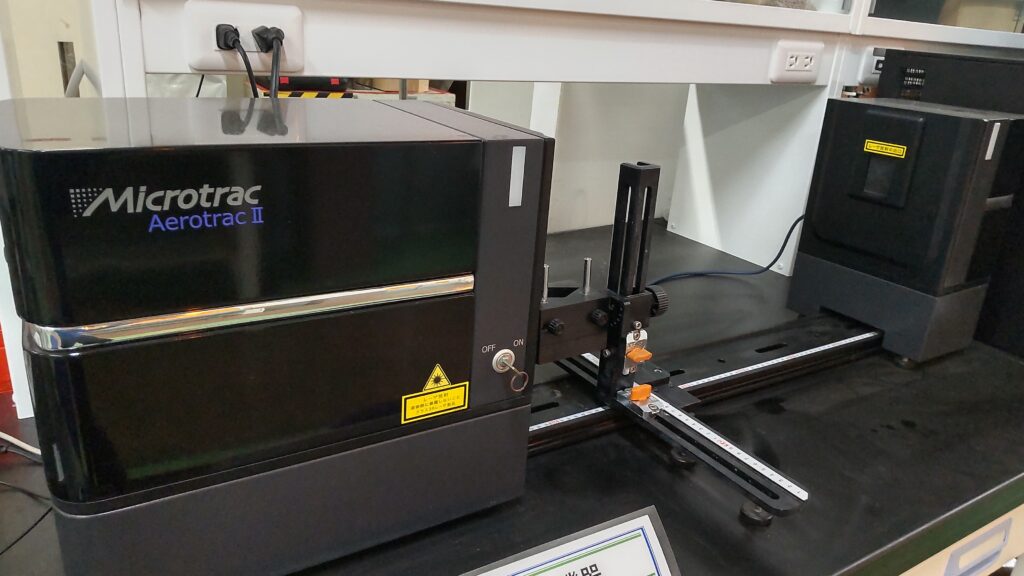

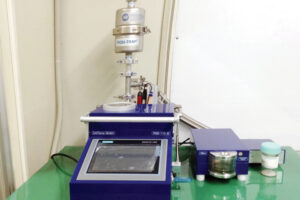

Spray particle analyzer

MicrotracBEL Aerotrac II

Laser diffraction particle size distribution analyzer. High-precision analysis of particle distribution of droplets discharged from nebulizers, injectors, and mist of humidifiers, at short measurement intervals.

Adhesion peel tester In-house production

In-house dedicated device specialized for peeling test of plating film on CFRP material. Peel strength can be quantified and graphed, and the maximum, minimum, and average values can be calculated.

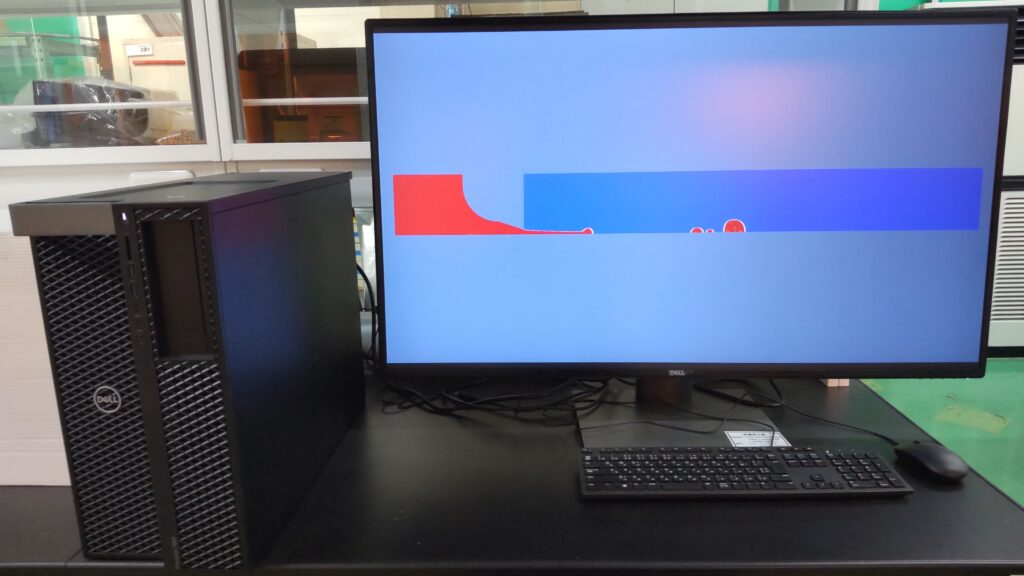

Workstation for fluid analysis

Cervo Ryzen Type RT3 PRO 3975WX

Equipment for designing and analyzing 3D mesh hole shapes for spraying, using in-house developed analysis software. It is possible to simulate the optimization of the spray performance before making a prototype, based on the viscosity and surface tension of the liquid to be sprayed.

Quantitative analysis instruments

Thermo Scientific ICP-AES iCAP6300 DUO

Sample is atomized, ionized and thermally excited, and the emission spectrums when it returns to the ground state are used to identify and quantify the chemical elements. Unlike atomic absorption spectroscopy, several types of elements can be analyzed at once.

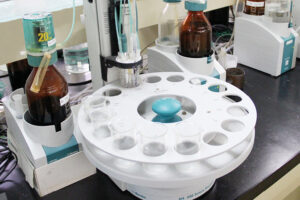

Metrohm Automatic Potentiometric titrator 905 Titrando

Precise measurement using a motorized burette and electrodes without the need for the necessary expertise for titration analysis.

Atomic absorption spectrophotometer

Hitachi Z-3300, Hitachi Z-5310

Qualitative and quantitative analysis of trace elements contained in aqueous solutions.

UV-Vis Spectrophotometer

Shimadzu UV-1700, Hitachi U-1500

Qualitative and quantitative analysis of molecules and ions in aqueous solution.

Surface analysis instruments

Scanning electron microscope (SEM)

JEOL JSM-6390LA

High-magnification observation of the sample surface using image from secondary electrons.

EDS (energy dispersive X-ray spectroscopy)

JEOL JSM-6390LA

Qualitative and quantitative analysis of chemical elements of the surface.

Color 3D laser microscope

KEYENCE VK-9700

Quantitative analysis of roughness and unevenness of the material’s surface.

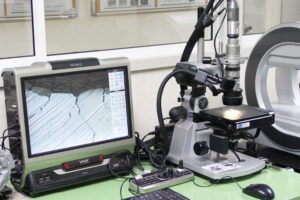

Digital microscope

KEYENCE VHX-2000

Magnification observation of the sample’s surface for visual inspection and detailed 3D observations.

High Accuracy Image Dimension Measurement instrument Keyence LM-1000

With high-magnification lens and CMOS image, high-precision measurement with a dimensional accuracy of ±0.1μm is possible.

Micro Vickers hardness tester

Shimadzu HMV-G

Vickers hardness (JIS Z 2244) & fracture toughness (JIS R 1607)can be conducted using this tester. Test force ranges from 9.8mN to 19.61N, with built-in digital camera and standardized automatic length measurement.

Rockwell hardness tester

Future Tech FR-X3

Rockwell hardness (JIS Z 2245) can be conducted using this tester. The maximum sample stroke is 221mm, cylindrical and spherical surfaces also can be measured.

Fluorescent X-ray film thickness measuring instrument

Hitachi High-Tech Science SFT9350

Non-destructive measurement of plating film thickness.

High-intensity X-ray beam irradiation and drift-type semiconductor detector enable measurement of small area and thin films.

Collimator size: Up to φ0.1mm can be measured.

Fluorescent X-ray film thickness measuring instrument Hitachi High-Tech Science SFT9550

Non-destructive measurement of plating film thickness. High-intensity X-ray beam irradiation and drift-type semiconductor detector enable measurement of small area and thin films. It is possible to measure the phosphorus content of electroless Ni-P plating.

Collimator size: Up to φ0.1mm can be measured.

Fluorescent X-ray film thickness measuring instrument

Hitachi High-Tech Science SFT3300

Non-destructive measurement of plating film thickness.

Large workpiece size of 300 x 400mm can be measured.

Collimator size: Up to φ0.1mm can be measured.

Fluorescent X-ray film thickness measuring instrument

Fisher Instruments XDL-B XYmZ

Non-destructive measurement of plating film thickness.

There is an opening on the housing, thus it is possible to measure large plate-shaped sample and tall workpiece (up to 100 mm).

Collimator size: φ0.3mm

Microscopic Area Spectrophotometer

Nippon Denshoku Industries VSS400

Non-contact measurement of spectral reflectance and spectral transmittance of a microscopic area using a microscope method.

Eddy current film thickness gauge

SANKO SDM-3100

Film thickness measurement of non-iron metals (aluminum, aluminum alloys, copper, etc.) or non-magnetic stainless steel (austenitic) surface-treated insulating films (alumite, paint, lining, etc.)

Electromagnetic film thickness gauge

Fisher Instruments FISCHERSCOPE MMS PC2

A multi-measurement system that can measure film thickness and material testing (conductivity, amount of ferrite structure, etc.) in one unit.

Solder checker

RHESCA SAT-5200

Solder wettability test for electronic parts, etc.

Solder dip bath

goot POT-103C, JAPANUNIX USS180D,HAKKO 487

Solder wettability test for electronic parts, etc.

Formic acid reduction reflow equipment

UNITEMP RSS110-S

Solder wettability test for automotive parts.

High temperature oven (high temperature dryer)

Yamato Scientific DR-22

MAX700℃, natural convection type with program operation function that control high temperature with high accuracy. It can be used not only as an electric furnace for ashing and sintering, but also as an incubator or dryer.

Annealing furnace

ESPEC PM-101

Workpiece can be annealed within the specified temperature range (from (ambient temperature +20)℃ to 300℃) and specified time.

Corrosion resistance tester

PCT tester

Hirayama PC-242RS

Reproduces a high-density steam atmosphere at 100℃ or higher, and increases the water vapor pressure inside the test chamber to an extreme level higher than the water vapor partial pressure inside the test component, thus shortening the amount of time it takes for water to enter the test component. Can be used for accelerated life test for moisture resistance evaluation of electronic component materials.

Constant temperature and humidity chamber

ESPEC LHU-114

Resistance evaluation test of component against sudden changes in temperature and humidity.

Constant temperature chamber

EYELA WFO-450D

Resistance evaluation test of component against high temperature heat treatment.

Salt spray tester

Itabashi Rika Kogyo SQ-800-S

Resistance evaluation test against corrosion using salt spray.

Low constant temperature and humidity chamber

Kusumoto Kasei SXN402

Durability evaluation by temperature and humidity cycle test.

Others

Cross-section polishing machine

Struers LaboPol-5

This machine is used for polishing the crosscut specimen for easier observation of the internal structure.

Cross section cutting machine

Struers Accutom-5

This machine is used for cutting specimen precisely without deforming it.